Repair and maintenance

MAINTENANCE

MAC valve actuator diagnostic device

Outline

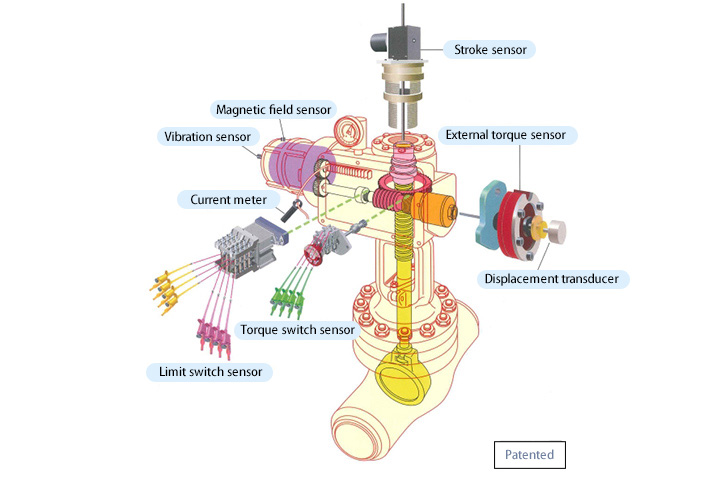

The MAC diagnosis is an advanced motor-operated valve diagnosis service developed by our company with many years of experience and achievements in the maintenance of motor-operated valves. Comparing a conventional overhaul to an inspection with surgical precision, the MAC diagnosis is comparable to a complete medical checkup utilizing sensor technology. Because the motor-operated valves transmit motor power from the worm, worm wheel, stem nut, and to the stem (valve shaft), the behavior and status of each part will be seen as a change in the torque. The MAC diagnosis accurately measures this torque change during operation to quantify comprehensive soundness in a short period for the check and evaluation procedure.

This enables the disassembly and repair of specific parts only when needed without unnecessarily disassembly of motor-operated valves.

Characteristics of MAC diagnosis

- – Checks the soundness of motor-operated valves quantitatively in a short period of time

- – Abundant experience in diagnosis and high precision operation

- – Measurement of torque during operation

- – Enables readjustment of the torque and limit settings on-site

- – Screening of valves subject to overhaul

- – Prevention of human error

- – Contribution to shortening of periodic inspections and cost reductions

- – Compatible with all motor-operated valves used in domestic nuclear power plants

Major diagnostic items

- – Insufficiency of preset torque value

- – Change in behavior of running torque value

- – Increase of valve pull-out torque

- – Stem nut abrasion volume

- – Motor current value

- – Motor brake operating time

- – Malfunction of electromagnetic switch in control panel

- – Abnormal vibration (such as backlash of transmission system and defect in bearing)

- – Limit switch operation position error

- – Torque switch bypass operation position error

- – Valve stop position error