Repair and maintenance

MAINTENANCE

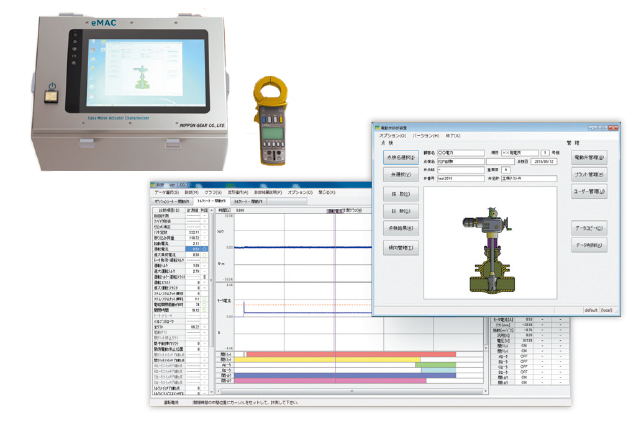

eMAC simplified valve actuator diagnostic system

Outline

Once the reference data is secured by measuring the torque data of the drive section of motor-operated valves during the first eMAC diagnosis, simplified diagnosis of deterioration and the abrasion statuses can be conducted by measuring the current value at the motor control center (MCC) in later diagnoses. Therefore, it can contribute to a reduction in the diagnostic and maintenance costs.

Features

- – The data recorded is electric current of one phase only.

- – The status of abrasion of stem nut threads can be determined without dismounting the drive section of motor-operated valves, which can contribute to preventive maintenance.

- –

- – The degree of deterioration and abrasion of the valves used in a wide variety of applications varies depending on the usage conditions. However, while conducting diagnostic tests many times, it becomes easier to determine the tendencies and set the timing of inspection and repair.

Because the basic design is the same as that of a detailed diagnosis, it is possible to grasp the situation accurately by conducting a current value diagnosis based on the actual torque during the first diagnosis, and it is highly reliable. - – As the torque data is gathered on-site, it assures a more accurate diagnosis.

Diagnostic items

- – Preset torque

- – Running torque

- – Valve pullout torque

- – Motor current

- – Switching time

- – Abrasion of stem nut threads

*eMAC is a simplified diagnostic device. If a more detailed diagnosis is requested, MAC is recommended.